Estrella production facilities are headquartered in Ettingen, Switzerland. Our location nearby Basel, Switzerland ensures ideal conditions for logistics, quality, and supporting infrastructure.

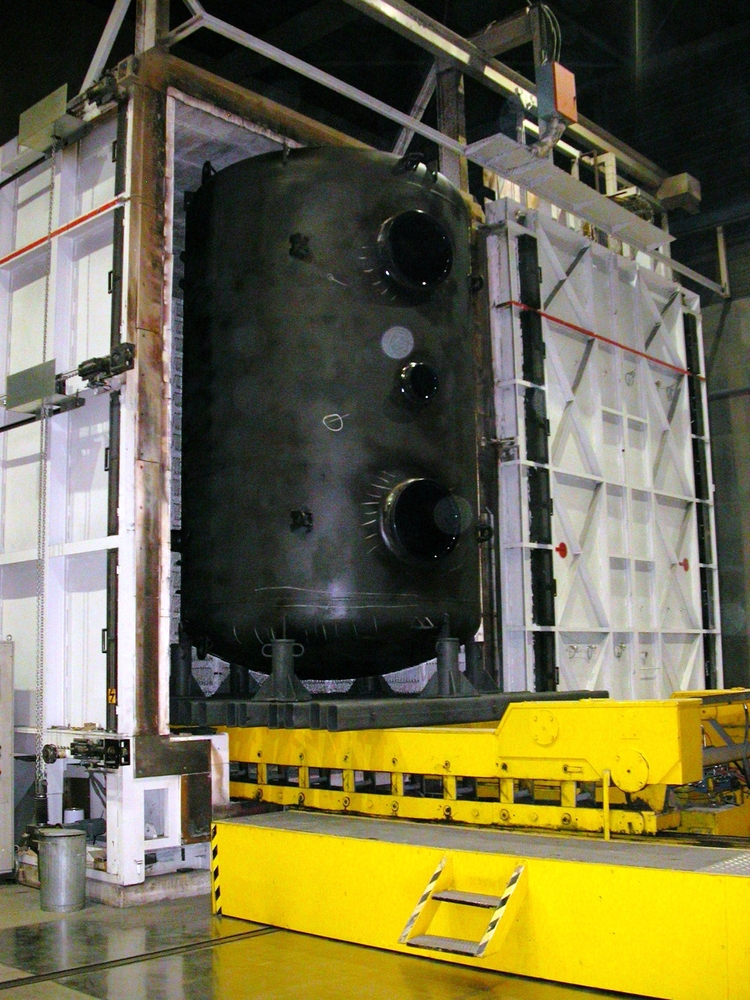

Two separate production lines, namely piping (40,000 parts/year) and large Apparatus (400 pressure vessels/year) are completely independent from each other in terms of equipment and qualified personnel. Our production equipment represents the latest state of the art technology:

Manufacturing devices for producing our own enamel

- enamel melting equipment for 30T/year

- slurry production with 4 ball mills for preparing 12 kind of different slurries

- research laboratory with test furnaces and devices for 100% testing of the glass production and development of new glasses

Manufacturing devices for piping production

- Computerized turntables with robotic feeds

- Automatic drilling machines

- Automated Welders for:

Full wire

Core welds

Submerged arc welding - automatic metal saws

- 4 horizontal Furnaces with 200 to 400 kW power for pipes up to 10 ft. length

- 2 blasting plants

Manufacturing Equipment

- Automated Welders for:

Full wire

Core welds

Submerged arc welding - Cylinder rolling machine for Plates up to 30mm thickness and 3 meter width

- Warm extruding device up to 600mm Nozzles on 30 mm plates

- Numeric gas cutting machine with 4 Heads

- Chamfering machines for weld preparation

- 1 blasting plant

- 1 vertical Furnace 2000 KW (for lining items up to 4.5meter L) + 1 vertical Furnace 1500 KW in planning

- 5 cranes (5t – 25t)

- 28 heat resistant firing devices enabling tolerances that are twice as good as DIN norms.